Copyright © 2017 -

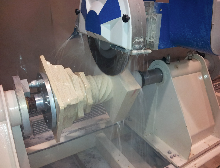

Donatoni Kronos 5 axis CNC FabCenter

The KRONOS is a 5 interpolated axes CNC cutting center, with automatic tools change and Z axis stroke of 400mm, 650mm or 800mm.

The KRONOS series allows to obtain accurately shaped products and an high productivity thanks to the X and Y axes, sliding on linear recirculating ball guides in oil bath.

Brushless motors and high precision gearboxes are used for all axes drive.

Given the multiple variety of work processes, the KRONOS is equipped with a wooden table for cutting operations, and with a fixed/tilting table with aluminum top, and vacuum pump and suckers to clamp the slabs and then process works like shaping, polishing edges, cuts with end mills, polishing surfaces, drilling, digging, low reliefs and engravings.

This machine can be equipped with lathe and rotating table with rotating axis, both CN controlled, bringing the interpolated axes from 5 to 6.

|

Technical Specifications |

||

|

Max number of interpolated axes |

N° |

5/6 |

|

Vertical stroke Z axis |

mm |

400- |

|

Blade- |

gradi |

- |

|

Blade- |

gradi |

0 / 90° |

|

Working table dimensions |

mm |

2000 x 3500 - |

|

Maximum disc diameter |

mm |

625 to 725 / 24 to 28” |

|

Maximum cutting depth |

mm |

200 to 250 / 8 to 10” |

|

Spindle Power |

Kw |

13 to 17 / 17 to 22 HP |

|

Approx. total weight of the machine |

kg |

5000 / 11,000 lbs |